Be sure to follow my newest work at my new blogsite, miniatures by auralea!

Wednesday, June 23, 2021

Wednesday, October 25, 2017

Saturday, September 2, 2017

Dollhouse couch/sofa tutorial

The basics of this idea I got from Kris Compas who is really amazing when it comes to making furniture with these materials. You should check her out: http://1inchminisbykris.blogspot.com/

I found a sofa on the Ethan Allen website that I felt comfortable transforming to miniature for my Kinfeld dollhouse.

After thinking about it I decided to make the cushions first to determine the correct framing for the couch. I made the framing first last time I attempted a couch and everything was out of proportion. So I thought this would be easier for me personally.

We all have our own way of thinking and creating so I think it helps to stay flexible and go with what you know.

I used a Heidi Ott doll to determine my measurement. Don’t forget to use the room you will be putting it in as a guide too. Smaller room = smaller sofa!

Seat cushions

Cut 4 pieces of foam board to 2 7/8 x 2 1/4” . Glue the 2 pairs together.

Cut foam (two the same as above and two at 2 1/4 x 1 1/2”) and glue to board. Small first then large on top. Let dry.

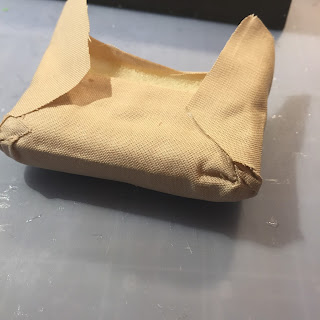

Glue material to back. Not too tight. You want a smooth cushion with a rise in the center.

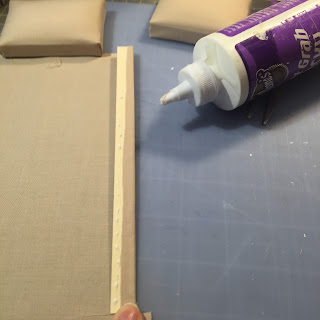

Cut 2 strips of card stock paper to 7/16 x 7 1/2”.

Glue to material as shown. Run glue along the edge of the fabric and lay the strip on top, press down. Fold over and put glue down the strip as shown and fold over. Press and let it set for a few minutes then trim off the extra down the center of the paper strip.

I first put the glue on the front of that trim strip but I didn’t smooth it out enough and the material puckered so I prefer no glue on the front, only on the back as I just did. You do what is easiest for you.

Glue the trim around the sides and front of the cushions.

Back cushion

Cut 2 foam board pieces and two foam pieces to 3 x 1 13/16”.

Cut 2 foam pieces 2 1/8 x 1 1/2”.

Sharpen that blade on your sharpening stone! I have saved a lot of money on blades since I started doing it this way. :)

Trim foam board as shown. On the second one I made I rubbed the top of the back cushion on the corner of my desk to get a slight indent. Might help it look more realistic. Your call.

Glue foam onto board. Small then large on the front of the cushion and one large on back.

Cover with fabric as shown. Front first.

Glue the back on.

Run glue along the straight edge of a 10” long piece of fabric.

Fold over about 1/8”. Trim fabric as shown.

More glue and fold again to have a 1/4” strip. Press with fingers.

Glue around back cushions edge. I didn’t use paper in this because it looked too stiff for a back cushion/pillow.

Take a break!

The couch frame

Cut two pieces of foam board at 6 3/4 x 2 1/4” and glue together. Round the corners. I rubbed mine on my board to smooth out.

Cut out two notches on the side for the arms. Glue gun in the sides (1 5/8 x 1 3/8” tall).

Use this diagram to cut your back template from a cereal box. Length is 10 7/8”.

With glue gun attach to one side and continue around to the back and to the other side.

Cut some mat board and wrap it around the top in two layers. Use the glue gun.

Lay the frame on a piece of cereal box about a half inch up from the base as shown. Trace around white wrapping the cardboard around the frame. Cut out the cardboard and glue to the back base and back top of the frame with the glue gun. I made a center mark first on the cardboard and frame so I would lay it in the glue properly.

Glue the sides.

Test fit your cushions.

Add in some thicker cardboard on the inside of the arms then put a piece if foam above it. Don’t go as long as I did. I had to trim the ticker cardboard it to fit in the back cushions. Keep test fitting as your building.

Wrap over the arm with felt. Glue with glue gun. Do the same for the back on the inside only.

I used spray Elmer’s glue on a piece of white cover stock and glued it to the back to cover up the boxes print.

Upholstering:

Check out Kris Compas’ post for detailed instructions on how to upholster.

She has very detailed instructions.

I will briefly explain how I did mine. I used Tacky Glue for this.

Upholster the front base.

Upholster the back by glueing to the front of the arms first and then the underside and then drap over the top and glue on the inside.

Upholster the front of the arms.

Upholster the arms to the inside and the back on the inside to the top edge.

I sewed some throw pillows.

Then cut the legs from mat board and paint them. I made a stencil and glued two cut legs together until I had four.

I hope this helps someone. Ask any questions. I am sure I missed something, it was a lot of work to provide this tutorial. :)